Welcome to | DataLyzer

Integrated Solution for Quality, Productivity and Process Improvement.

Energize your solutions with our global experience; 4000 customers, 40+ years!

One-Click access to your Quality and Production Data from heterogeneous sources

Over 40 years of experience.

DataLyzer provides training, consultancy and software solutions for process improvement and quality control. Our software suite consists of FMEA, MSA, SPC, OEE and APQP software.

DataLyzer was the first company ever to sell commercial SPC software and Gage R&R software dating back to 1979.

Our 40+ years of unsurpassed support for SPC software implementation across six continents has resulted in our invaluable experience in training and implementation. Our understanding of customers’ challenges and our innovative solutions have empowered corporations to dominate the market and achieve manufacturing excellence.

Scalable Comprehensive Manufacturing Solutions

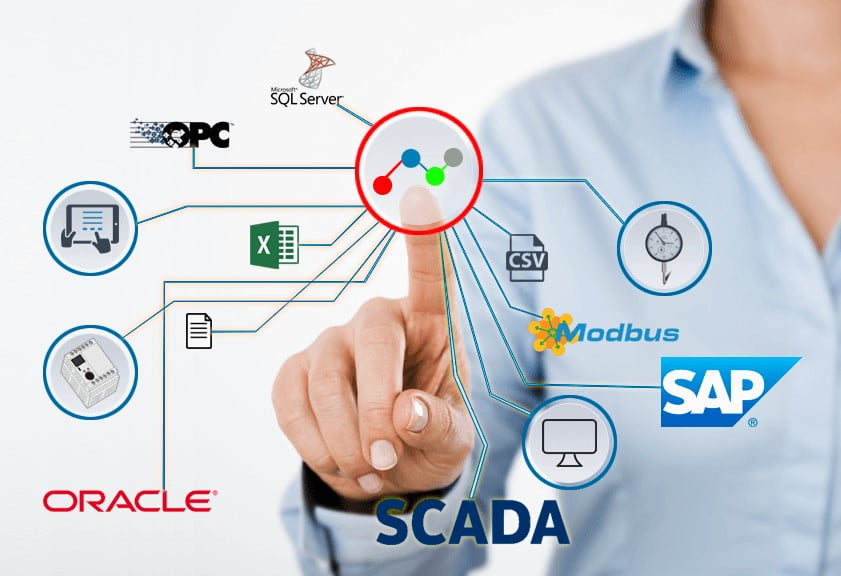

DataLyzer offers a flexible and scalable solution that enables customers to start with a single station module, expand to a plant-wide integrated solution (SPC, Process Flow, FMEA and Control Plan, Calibration and MSA, real-time OEE and APQP) and support a company-wide network (Saas or on-premise) with users in multiple locations. Future IT architecture is supported by implementing containerization (Docker) in all our solutions.

Our solutions are engineered to import data automatically from a variety of sources and are available in 21 languages to cater to solutions around the world. With a quick setup, our user-friendly software can be implemented extremely fast.

Localized Presence and Global Support

Sustainability and Continuous Improvement is getting more and more important. Our local presence allows our customers to reach us easily and connect with our local trainers and consultants without extensive travel requirements. Our global footprint will help you get the best local support achieving Global Benefits.

What Others Say About Our software

Products

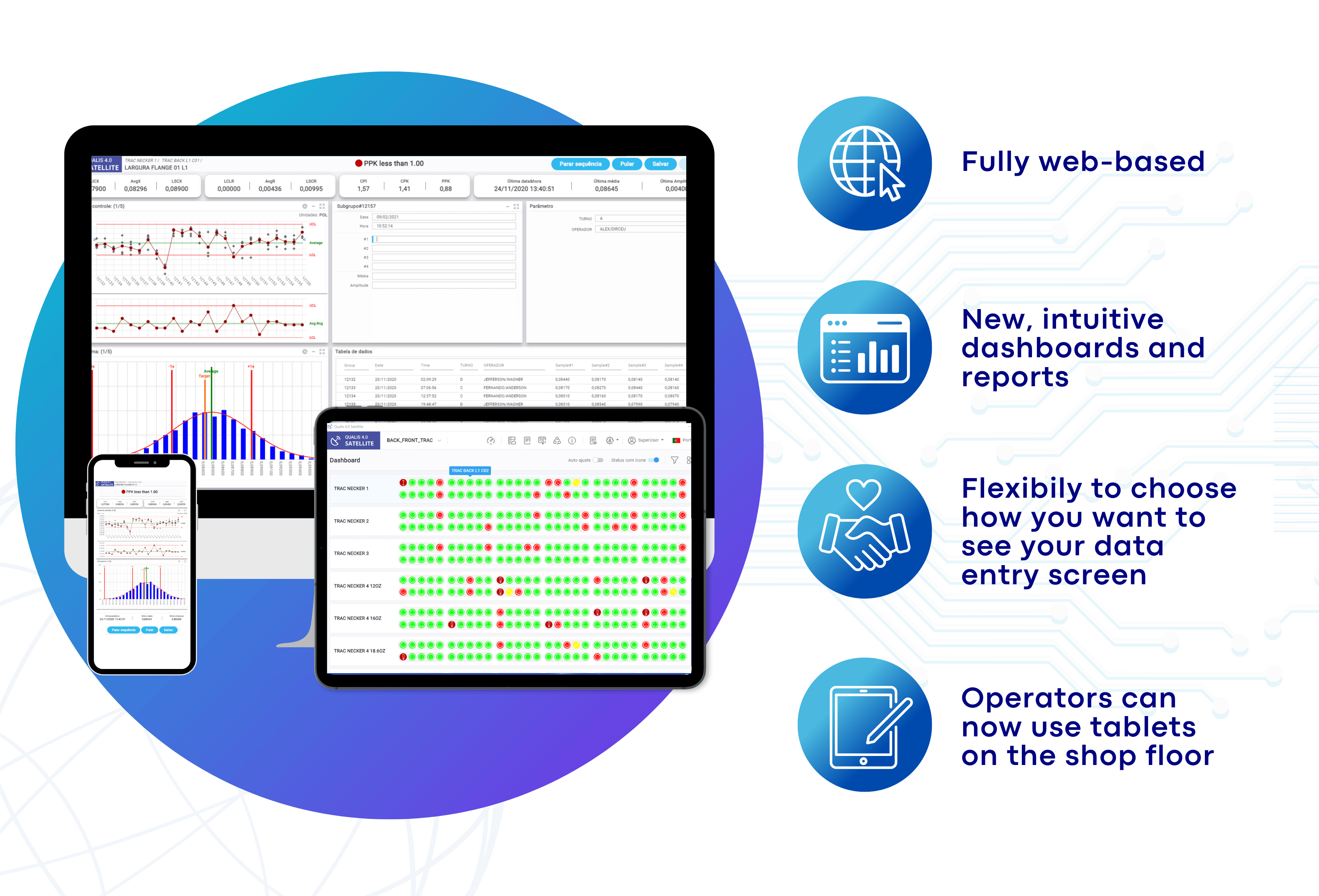

SPC software

DataLyzer® Qualis is a comprehensive webbased SPC software solution simplifying the tasks of real-time data collection and charting and analysis…

Gage Management

DataLyzer® Qualis webbased Gage Management software supports gage registration, calibration and full MSA functionality...

FMEA software

DataLyzer® webbased FMEA module seamlessly allows easy creation and management of DFMEA, Process FLow, PFMEA and Control Plan....

OEE software

DataLyzer® OEE software is a real time OEE module allowing manual and automatic OEE data collection...

Qualis Analytics

DataLyzer Qualis Analytics is a complete webbased SPC analysis module including AI and much more

APQP software

DataLyzer® APQP is a webbased workflow software that helps to manage your APQP (3th edition) process...